Conventional vacuum pumps remove non-condensables (usual gases).

At the heart of our expertise lies confinement zeodration, a revolutionary dehydration technique exploiting the exceptional properties of zeolites. Our process offers unprecedented flexibility, allowing the precise adjustment of pressure and temperature to meet the specific quality criteria of each product, ensuring optimal performance.

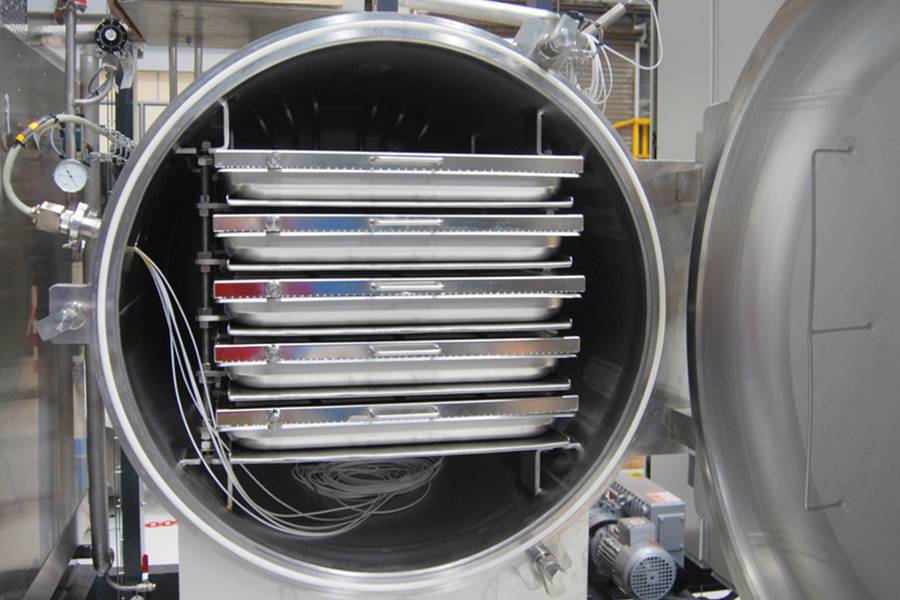

The product is loaded into the enclosure (tank, churn, tunnel).

The enclosure is placed under vacuum and can reach pressures below 100 Pa.

The product is then treated at a positive or negative temperature depending on its sensitivity as well as the type of drying envisaged.

The duration of the cycle depends on the ability of the product to release water.

Once the desired residual humidity has been reached (it can be reduced to a value below 1%), dehydration is complete.

The vacuum is then “broken” and the product is unloaded.

Innovation and flexibility : Our technology pushes the boundaries of dehydration by providing unparalleled flexibility and adaptability.

Quality optimization : Precise customization of processing ensures that your products maintain their excellence.

Sustainability and energy efficiency: Contribute to a sustainable future by choosing an energy-efficient drying process.

Conventional vacuum pumps remove non-condensables (usual gases).

A special clay, our water trap, only fixes water vapor.

Containment of the product in the tank covered with its adsorbent filter cover.

Contact us at +33 (0) 6 37 03 06 04 or via our online form.